What processing machinery and equipment are required for jewelry processing

In the past, gold jewelry processing relies on traditional handicrafts, processing efficiency is slow, style and quality can not meet the pursuit of modern people's fashion, with the progress of the times, gold jewelry processing has been gradually replaced by automated equipment, efficiency effectively improved, save workers' production costs, equipment processing styles are diverse, exquisite and delicate quality, changed the modern people's concept of gold jewelry customs, then what equipment is needed for gold jewelry processing?

A noble and exquisite gold jewelry finished product, need to be made of multiple processes, gold jewelry is diverse, to Buddha bead chain as an example, in general, semi-finished product processing has three major processes: cutting, turning, welding, the following is introduced one by one.

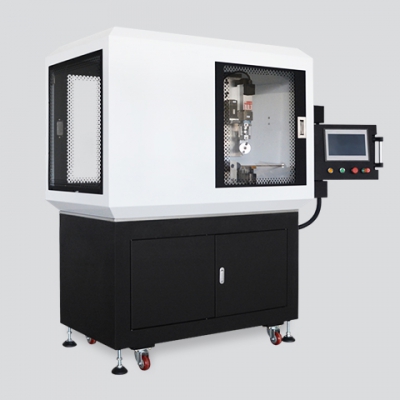

Jewelry cutting equipment: automatic gold melting machine, tablet pressing machine, wire pulling machine, double-head welded pipe machine, pipe drawing machine, automatic hammering machine, positioning pipe cutting machine, automatic bead grinding machine.

Jewelry car equipment: automatic car ball machine, automatic car olive ball machine, automatic car pipe machine.

Jewelry welding equipment: automatic touch welding machine.

Each process and each equipment, greatly save time, in the past each process workshop has a large number of workers, divided into two or three shifts of work, now with automation equipment, a person can take care of several equipment, and each equipment can operate 24 hours, the thickness of the bead tube can do a few wires, but also carving patterns, traditional handicrafts are completely unable to do, the accuracy of welding is <>%, the important thing is that the solder joints are very small, and no solder welding ensures the purity of the finished product.

English

English 简体中文

简体中文